The gentle method enables eco-friendly recycling of solar cells

[ad_1]

(Nanowerk News) There are currently two main types of solar cells. The most common are silicon-based and account for 90 percent of the market. The other type is called a thin film solar cell which in turn uses three main sub-technologies, one of which is known as CIGS (Copper Indium Gallium Selenide), and consists of layers of different metals, including indium and silver. Thin film solar cells are by far the most effective of the currently commercially available technologies. They can also be made bendable and adjustable, which means they can be used in a wide variety of fields.

The problem is that the demand for indium and silver is high, and the increase in production is accompanied by an increase in the amount of production waste that contains a mixture of valuable metals and hazardous substances. Being able to separate the metal of interest from other substances is, therefore, extremely valuable, both economically and environmentally, because it can be reused in new products.

“It is very important to remove contamination and recycle it, so that the material is as clean as possible again. Until now, high heat and large amounts of chemicals have been used to succeed, which is an expensive process that is also not environmentally friendly,” says Ioanna Teknetzi, PhD student in the Department of Chemistry and Chemical Engineering, who with Burcak Ebin and Stellan Holgersson published the results. new to the journal Solar Energy Materials and Solar Cells (“Recycling of precious metals from thin film CIGS solar cells by washing under mild conditions”).

Now their research shows that more environmentally friendly recycling processes can produce the same result.

“We took into account purity and environmentally friendly recycling conditions and studied how to separate metals in thin film solar cells in acidic solutions in a more ‘friendly’ way using a method called leaching. We also have to use chemicals, but not as much as the previous washing method. To check the purity of recovered indium and silver, we also measured the concentrations of possible impurities and saw that optimization can reduce them,” says Ioanna Teknetzi.

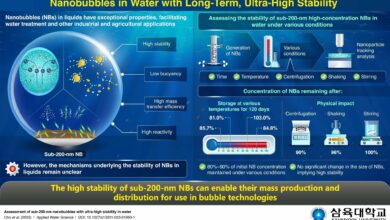

Researchers point out that 100 percent silver and about 85 percent indium are recoverable. The process takes place at room temperature without adding heat.

“It takes one day, which is a bit longer than the traditional method, but with our method, it becomes more cost-effective and better for the environment. We hope that our research can be used as a reference for optimizing recycling processes and pave the way for using the method on a larger scale in the future,” said Burcak Ebin.

Method

1. Films from solar cells are analyzed with respect to material, chemical composition, particle size and thickness. The solar cell is placed in a container with an acid solution at the desired temperature. Agitation is used to facilitate the dissolution of metals in acidic solutions. This process is called washing.

2. The effectiveness of leaching and chemical reactions is assessed by analyzing samples taken at certain times during the leaching process. Different metals are washed at different times. This means the process can be stopped before all of the metal has started to dissolve, which in turn helps achieve higher purity.

3. After leaching is complete, the desired metal is in solution in ionic form and can easily be purified for reuse in the manufacture of new solar cells.

[ad_2]

Source link