X-rays are helping researchers learn new tricks from old metals

[ad_1]

(Nanowerk News) A team of researchers led by the US Department of Energy’s (DOE) Argonne National Laboratory used powerful beams of X-rays to unlock new understanding of materials critical to the production and use of hydrogen. The goal is to make hydrogen production and use more efficient and less expensive, offering a better fuel for transportation and industry.

These findings have been published in Nano Letters (“Nanooperandoscale Imaging of Electrochemically Induced Strains in Locally Polarized Pt Grains”).

“Efficient hydrogen production is key,” said Hoydoo You, senior physicist at Argonne. “Hydrogen is the lightest energy storage material. Hydrogen can be produced from water using renewable or excess energy, transported as a fuel, and converted back into water to produce energy for consumers. Platinum and its alloys are the best at catalyzing and enhancing the water splitting process by accelerating the exchange of electrons.”

Understanding and developing materials that enable the efficient production and use of hydrogen is key to the hydrogen economy. The researchers are taking the first steps in developing tools that will allow them to characterize materials with new levels of detail, ultimately leading to the best materials for hydrogen production and use.

“This will make the production and use of hydrogen cheaper and more environmentally friendly,” You said.

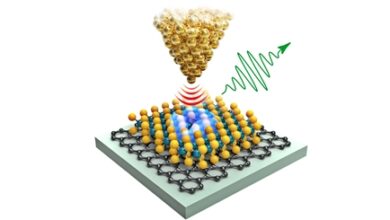

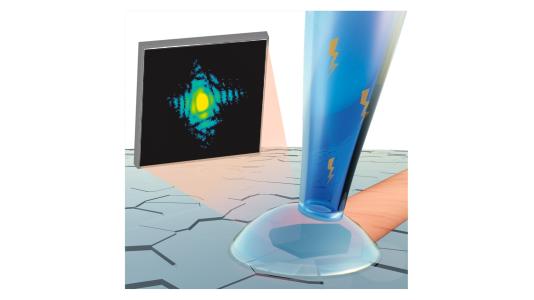

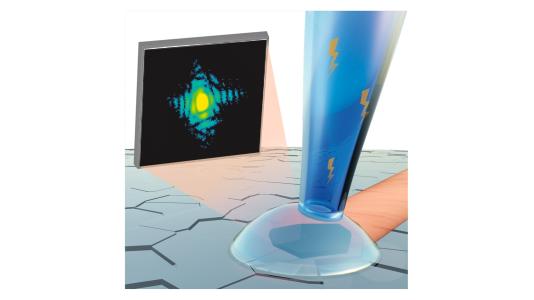

The research team made use of the Advanced Photon Source (APS), a user facility of the DOE Office of Science in Argonne. Working at the APS, the researchers aimed an intense X-ray beam at a single grain of platinum. The diffraction patterns of the grains are collected on an X-ray detector. The pattern is converted into a sample image using a customized computer algorithm.

A nanodroplet chemical cell, constructed with a tiny pipette tip (a device for making small droplets of liquid), is used to control the chemical reaction that occurs in platinum grains to produce hydrogen in an electrolyzer. Electrolyzer is a device for producing hydrogen fuel from water using electricity; devices in reverse operation, known as fuel cells, convert hydrogen fuel back into electricity.

“The reaction is controlled by applying a voltage, directed through the electrolyte in a nanopipette to the grain being studied,” says Argonne physicist Matt Highland. He designed an early prototype of this new tool. This prototype enables single nanograin probes and opens the door for realistic all-grain scanning capabilities in electrolyzers or fuel cells when APS upgrades are complete. He also assisted with data collection and experiments.

Physicists Argonne Ross Harder and Wonsuk Cha worked on APS beamline 34-ID-C, where the experiment was conducted, and helped integrate the new electrochemistry tool into their existing instruments.

“The ability to do localized electrochemistry while creating new pictures of how something happens, at the single-particle level, is truly extraordinary,” said Harder.

Current APS provide X-ray beams that are up to a billion times brighter than those used by dentists. But the extensive upgrades will make the APS even more powerful. When the upgraded APS enters service in 2024, its X-ray beam will be 500 times brighter than today. That is, the technique as used in this study will get better after upgrading.

“The APS enhancements will help us see things happening in real time in materials,” says Harder. “Measurement times can become fast enough that we can move from one particle to another, and we can see how they interact with the electrochemical environment and with each other.”

“Important processes such as battery charge and corrosion require real-time grain imaging to understand the full picture of the process,” said assistant physicist Argonne Dina Sheyfer. “We believe the added brightness of upgrading APS with our new tools will enable studies we can only dream of today.”

[ad_2]

Source link