High-quality 2D nano sheets can be reached with a single drop

[ad_1]

(Nanowerk News) A research group led by Professor Minoru Osada (he, he) and postdoctoral researcher Yue Shi (he, he) at the Institute for Future Materials and Systems (IMaSS), University of Nagoya in Japan, has developed a new technology for making nanosheets, films a thin layer of two-dimensional material several nanometers thick, in about a minute. This technology enables the one-click formation of large, high-quality nanosheet films without the need for special knowledge or technology. Their findings are expected to contribute to developing industrial manufacturing processes for various types of nanosheet devices.

The study was published in ACS Applied Materials & Interfaces (“Automatic One-Drop Assembly for Easy 2D Film Deposition”).

Nanosheet has a thickness that is measured in nanometers. Nanometers are so thin that the sheet cannot be seen from the side with the naked eye. They have potential uses in several different fields, including electronics, catalysis, energy storage, and biomedicine. Those made of graphene and inorganic nanosheets are being tested for use in a variety of devices, from solar cells to sensors and batteries, because they have different electrical, transparency and heat-resistant functions than conventional bulk materials.

However, current techniques used to prepare these films, such as the Langmuir-Blodgett method require sophisticated operating skills and conditions. “Using existing methods, it takes about an hour to make one layer,” said Osada. “This creates a huge bottleneck in nanosheet manufacturing.”

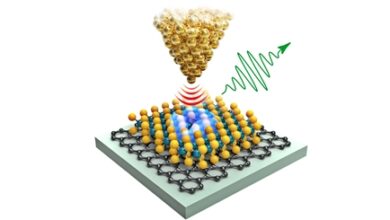

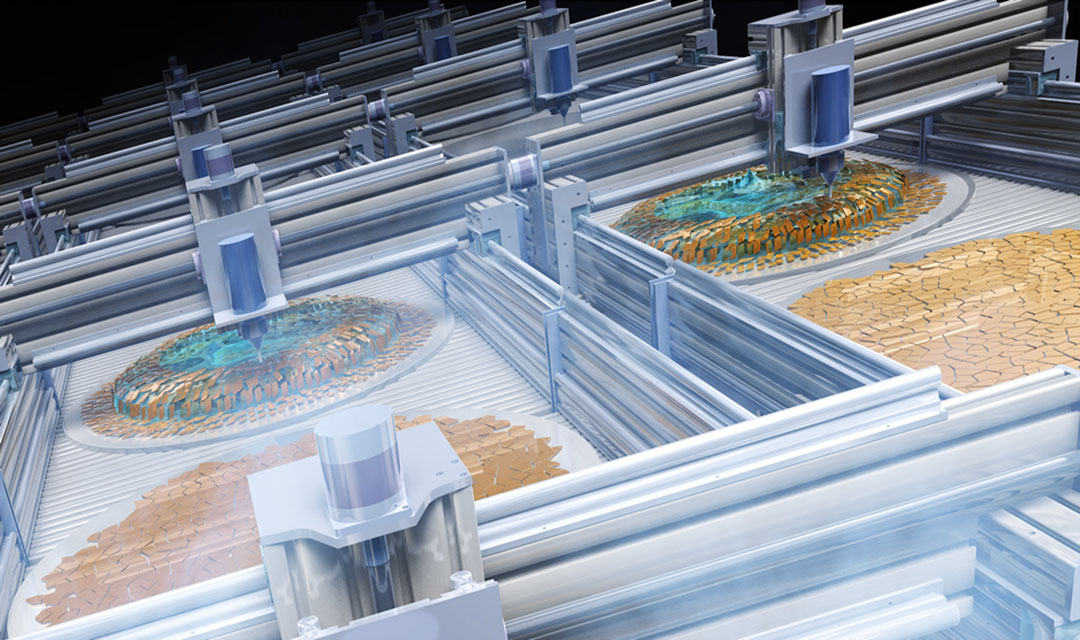

The group aims to develop a new process that can produce high-quality monolayer nanosheet films easily and in a short time. They developed an automated film forming process that produces nanosheets in about one minute by dropping a drop of an aqueous colloid solution onto a substrate heated on a hotplate using an automated pipette. After that, they followed it up with aspiration of the solution and draining of the liquid. The result is a neatly tiled monolayer film with no gaps between the nanosheets.

“The reduction of the surface tension of colloidal aqueous solutions and the promotion of convection of the nanosheets suppressed the overlap and gaps between the nanosheets and allowed us to control their alignment,” said Osada. “Layer-by-layer construction of multilayer films controlled by nanosheet thickness units was made possible by repeating neat tiled single-layer film fabrication operations.”

“This newly developed method is expected to become an important technology as an industrial thin-film fabrication method and a nano-coating method for nanosheets because it is simple, fast, and requires little solution to fabricate high-quality, large-area films with neat tile alignment,” said Osada. “This technology is based on a simple drip and aspiration operation using an automatic pipette and does not require special knowledge or technology. This technology is applicable to nanosheets of various compositions and structures, such as oxide, graphene and boron nitride, and can form films on substrates of various shapes, sizes and materials, making it a very versatile film forming technology.”

[ad_2]

Source link