Robots Blog | fruitcore robotics launches new operating system with integrated AI co-pilot: a big step in industrial automation for better efficiency, user friendliness and time

[ad_1]

Constance, 28/06/2023 – fruitcore robotics take industrial automation to a new level with an innovative operating system that uses the latest AI technologies. With horstOS, industrial companies have new tools that support them every step of the commissioning of all applications with HORST intelligent industrial robots and significantly reduce complexity. With integrated AI co-pilot, industrial companies can increase the efficiency of their production processes and save time. “Generative AI is driving change in many domains. This new technology will transform automation and give our customers a whole new automation experience,” said Patrick Heimburger, Chief Revenue Officer at fruitcore robotics.

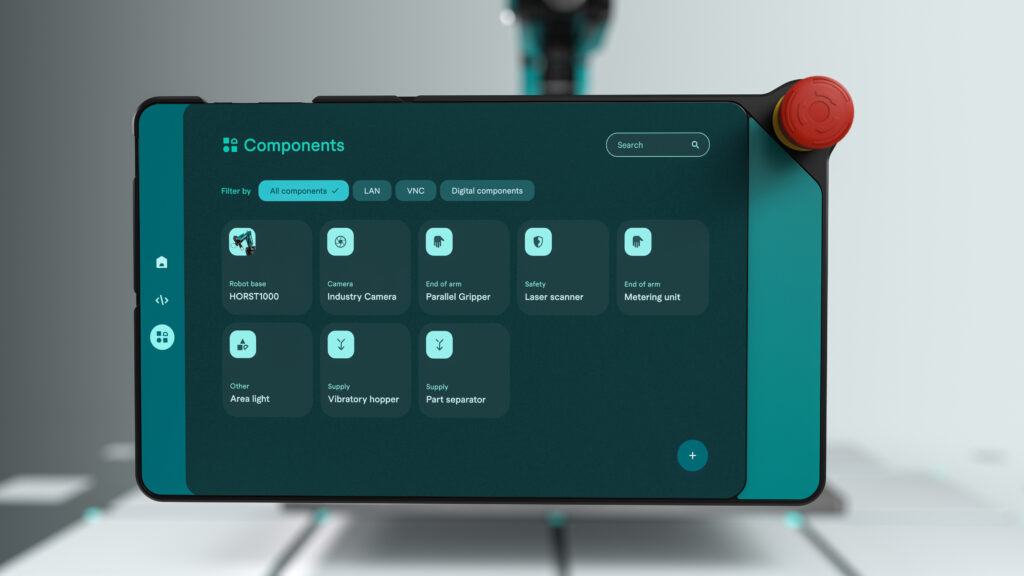

The new operating system from fruitcore robotics simplifies and accelerates the configuration and management of all the components involved in the processing, programming and operation of fully managed applications. All control of existing industrial robots, components and processes is carried out through a user-friendly interface, which makes their interaction even easier to implement. horstOS basically consists of three interconnected areas: component management area, area for

programming and process control. These three areas offer users all the functionality they need to quickly, easily, and efficiently set up and use their entire system. In the area of component management, thanks to the standard interface, the user can seamlessly integrate and centrally manage all relevant components of the entire system, such as the gripper, camera system and safety system. Components can be added with one click and it is possible for any component that has a web application or digital interface – regardless of the manufacturer. If status information is to be queried for any of the connected components, settings checked or changes made, this can be easily implemented through the robots panel with horstOS as the central user interface. When users move on to the programming area, they find themselves in the intuitive horstFX operating software, where they create a program sequence for the robot, including all components. Once the program flow is set, it can be started, stopped, or paused in the process control area. The process control section also allows users to customize process operations and monitoring to suit their individual needs and specific processes. With the help of widgets, relevant process data can be displayed, the status of connected components can be displayed and parameters that need to be adjusted frequently can be accessed. It gives users complete control over their automation process.

Ask HORST Anything – AI Copilot helps in all phases of industrial robot life

“Our new operating system includes state-of-the-art technology and deep artificial intelligence integration. According to Patrick Heimburger, this sets a new standard for the rapid integration of industrial robots into processes such as machine loading and unloading, quality assurance, part separation or the application of adhesives and sealants. With AI Copilot on horstOS, users receive an intelligent assistant that supports them in natural language in real time to successfully master automation challenges. Whether setting up robots and other components, troubleshooting or suggesting program blocks, or even writing entire programs, AI Copilot enables users to quickly and precisely find solutions for their applications and keep operations running smoothly. If the user wants to know, for example, how he can transfer the position of a part determined by the camera to the robot, he can send this question to the AI co-pilot via a text prompt and will receive the appropriate code module within a few moments.

AI Copilot from fruitcore robotics is based on ChatGPT and specially trained for industrial needs. It offers users comprehensive access to all relevant instructions, supporting content and software documentation of the fruit core robot. To offer users an optimal user experience, the Constance-based company relies on the constant expansion of Copilot’s AI capabilities.

Future-oriented automation with horstOS

The range of services offered by horstOS will also continue to expand over the coming years. The operating system’s modular structure has made it possible to integrate external software and services effortlessly. User-specific software programs and interfaces from OEMs can also be seamlessly integrated. “With horstOS, the future of automation is a new reality. This system offers extensive support, even for those with little knowledge, and lower

effort involved in setup, operation and aftersales,” explains Jens Riegger, CEO of fruit core robotics. “Our intelligent industrial robots should not only offer our customers the best return on investment in the robot market. Especially against a backdrop of a ubiquitous shortage of skilled workers, they should also help increase productivity and save valuable time,” said Jens Riegger.

similar posts

[ad_2]

Source link